High-Durability WPC Building Formwork Mold for Superior Construction Applications

- Information

- Product Description

- Video

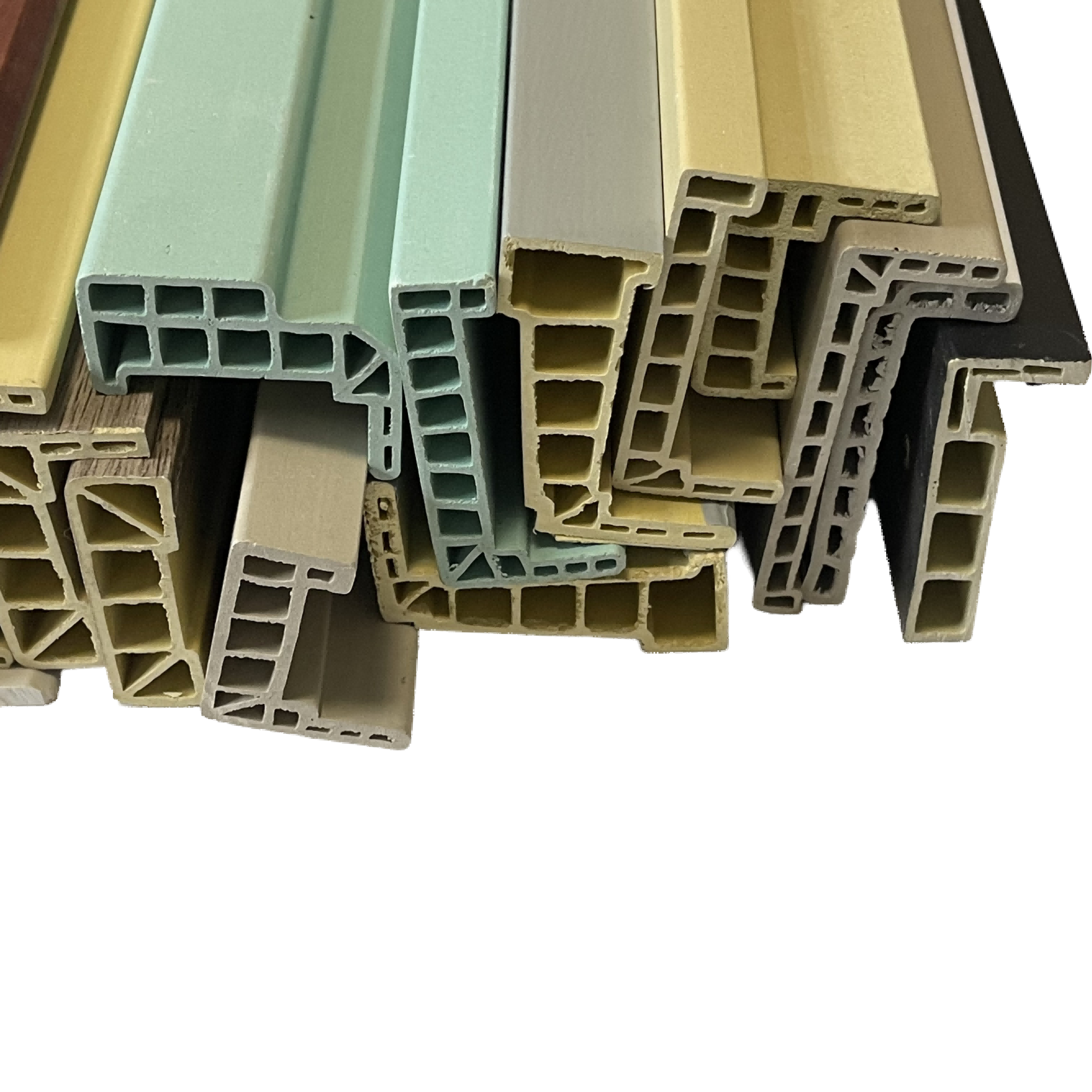

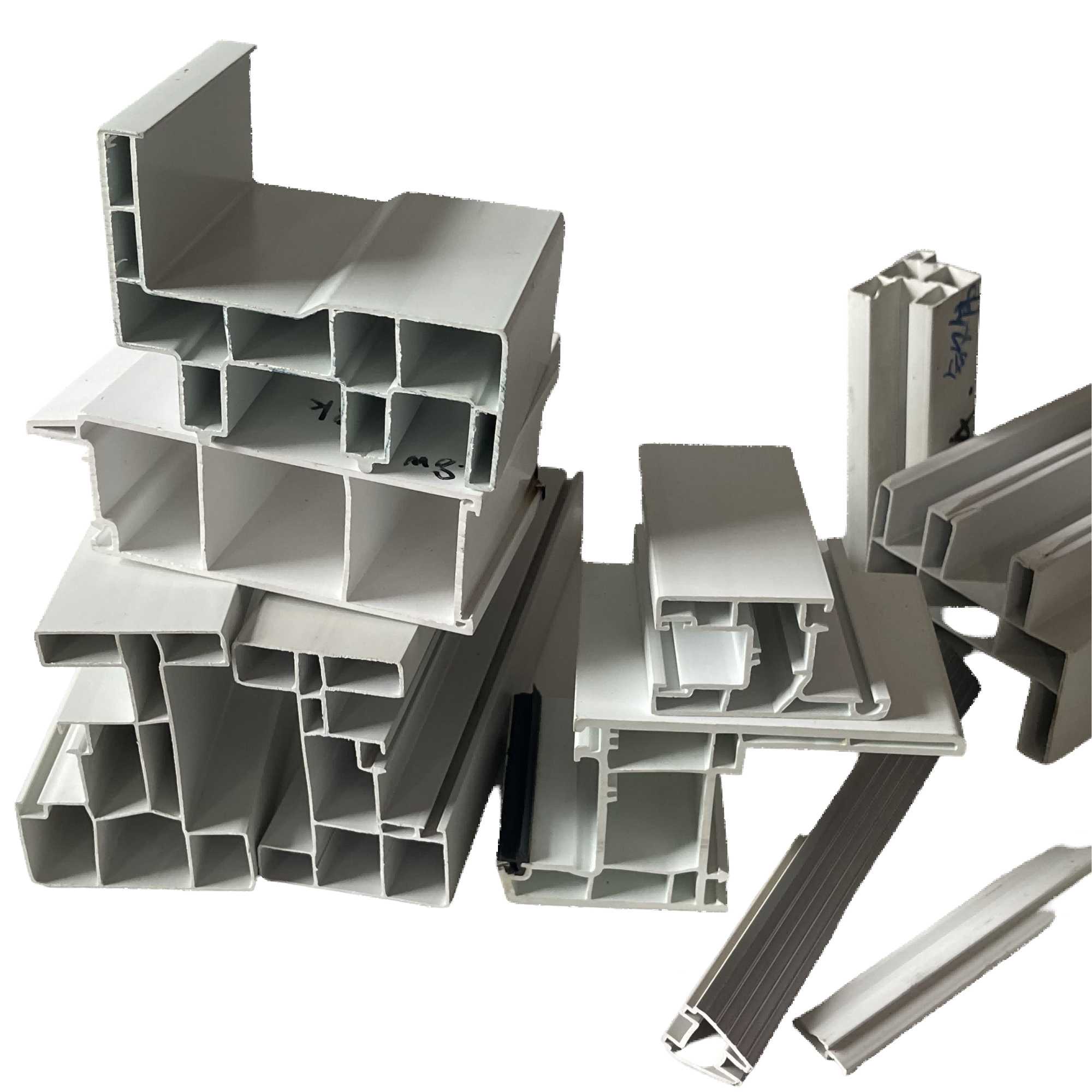

Material Compatibility: The mold is optimized for the production of WPC formworks, combining the strength of plastic with the natural aesthetics of wood. This results in formworks that are lightweight yet strong, with excellent resistance to environmental factors such as moisture and UV exposure.

High Precision and Consistency: Designed with cutting-edge technology, the mold ensures precise dimensions and uniformity across all formwork panels. This precision reduces material waste and ensures a perfect fit on-site, improving construction efficiency.

Durability: The WPC formworks produced using this mold are highly durable, offering extended life cycles compared to traditional materials. They resist cracking, splitting, and rotting, even in harsh weather conditions, reducing long-term maintenance costs.

Eco-Friendly Solution: By using recycled plastic and sustainable wood fibers, the mold supports the production of environmentally friendly formworks. This aligns with modern construction practices focused on reducing carbon footprints and promoting sustainability.

Customization Capabilities: The mold can be tailored to produce formworks of various shapes and sizes, accommodating the specific needs of different construction projects. Whether for complex architectural designs or standard building structures, this mold offers versatility.

Ease of Use: The WPC formworks produced are lightweight and easy to handle, simplifying installation and removal on-site. Their non-stick surface ensures that concrete does not adhere, making the cleaning process straightforward and quick.

Cost-Efficiency: The longevity and reusability of the WPC formworks result in significant cost savings over time. The mold's ability to produce high volumes efficiently further contributes to reduced production costs.

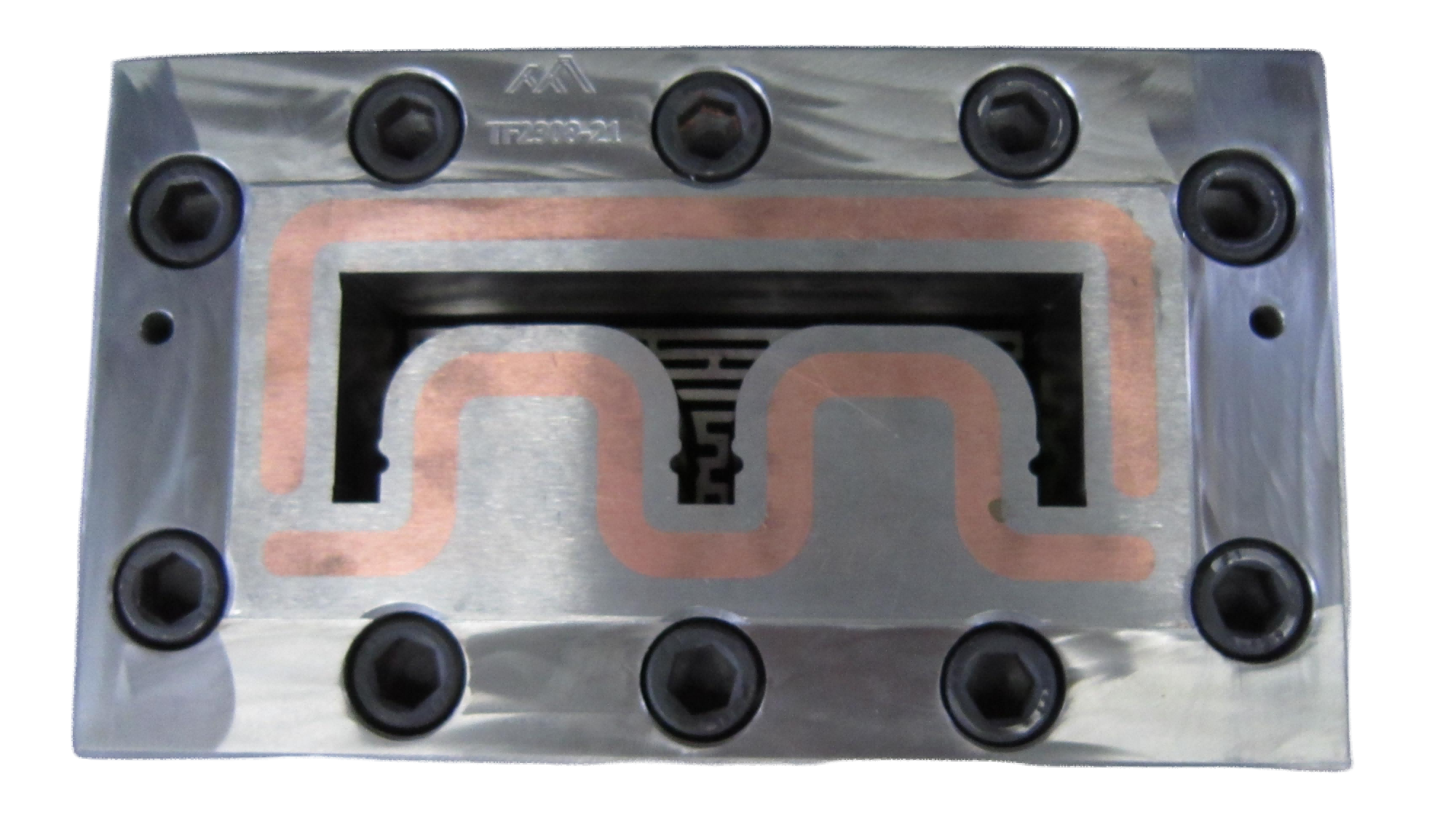

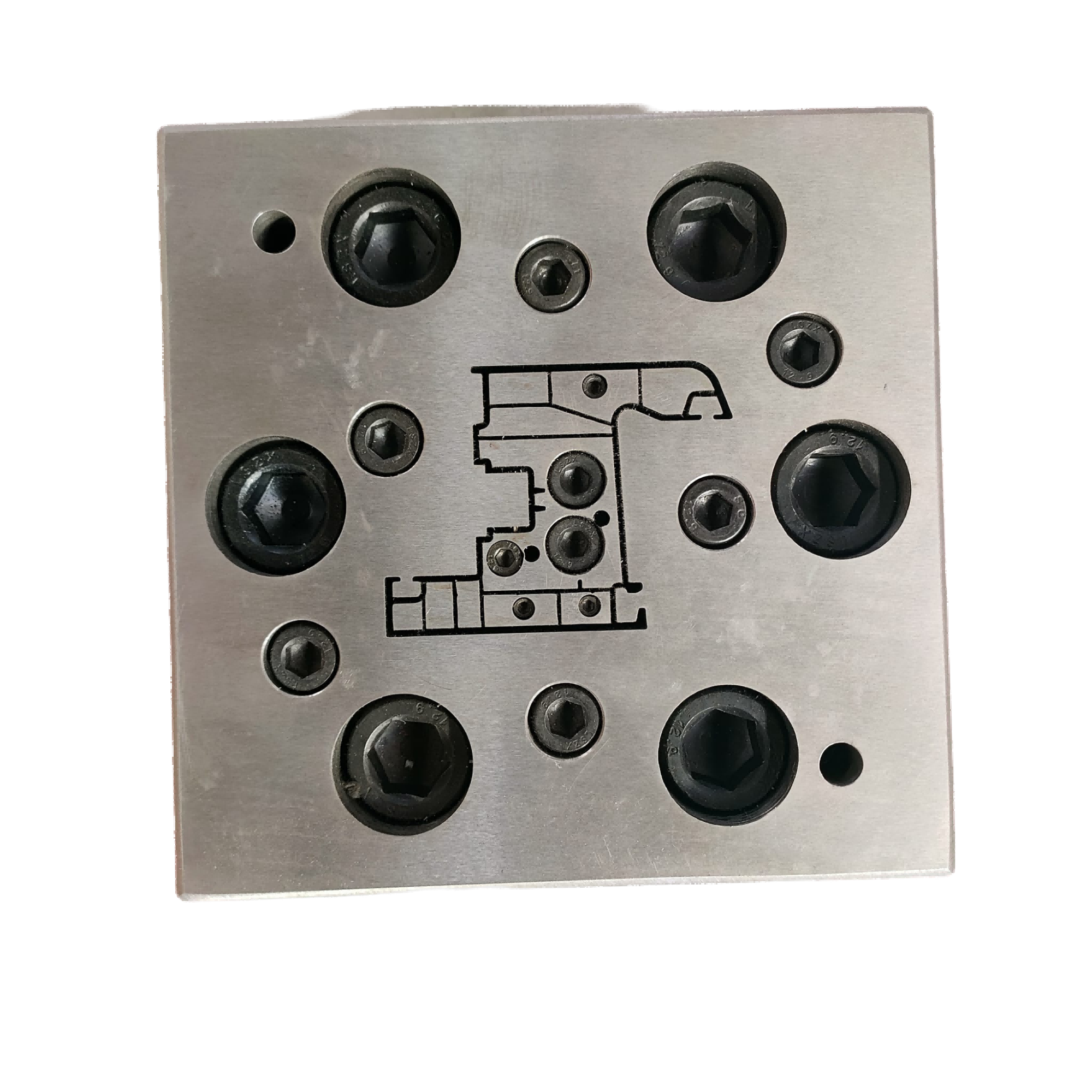

Advanced Mold Construction: Built from high-quality steel, the mold is designed to withstand high-pressure injection molding processes. It features superior resistance to wear and tear, ensuring consistent performance over long production runs.

The WPC Building Formwork Mold by Xishui Tongfeng Technology Co., Ltd is engineered to produce high-performance wood-plastic composite (WPC) building formworks. These formworks are designed to offer exceptional durability, environmental sustainability, and ease of use in various construction applications. Ideal for large-scale infrastructure projects and residential developments, this mold ensures the consistent production of formworks that are resistant to warping, corrosion, and moisture, making them a superior alternative to traditional wood or steel formworks.

Product Details:

Material Compatibility: The mold is optimized for the production of WPC formworks, combining the strength of plastic with the natural aesthetics of wood. This results in formworks that are lightweight yet strong, with excellent resistance to environmental factors such as moisture and UV exposure.

High Precision and Consistency: Designed with cutting-edge technology, the mold ensures precise dimensions and uniformity across all formwork panels. This precision reduces material waste and ensures a perfect fit on-site, improving construction efficiency.

Durability: The WPC formworks produced using this mold are highly durable, offering extended life cycles compared to traditional materials. They resist cracking, splitting, and rotting, even in harsh weather conditions, reducing long-term maintenance costs.

Eco-Friendly Solution: By using recycled plastic and sustainable wood fibers, the mold supports the production of environmentally friendly formworks. This aligns with modern construction practices focused on reducing carbon footprints and promoting sustainability.

Customization Capabilities: The mold can be tailored to produce formworks of various shapes and sizes, accommodating the specific needs of different construction projects. Whether for complex architectural designs or standard building structures, this mold offers versatility.

Ease of Use: The WPC formworks produced are lightweight and easy to handle, simplifying installation and removal on-site. Their non-stick surface ensures that concrete does not adhere, making the cleaning process straightforward and quick.

Cost-Efficiency: The longevity and reusability of the WPC formworks result in significant cost savings over time. The mold's ability to produce high volumes efficiently further contributes to reduced production costs.

Advanced Mold Construction: Built from high-quality steel, the mold is designed to withstand high-pressure injection molding processes. It features superior resistance to wear and tear, ensuring consistent performance over long production runs.

Company Profile:

Xishui Tongfeng Technology Co., Ltd is a leading name in the plastic mold manufacturing industry, known for its commitment to quality and innovation. Located in the historic city of Yellowstone, our company enjoys excellent transport links and a strategic industrial base. We specialize in the design and production of plastic molds, catering to a wide range of industries. Our advanced processing equipment, skilled workforce, and comprehensive after-sales service ensure that we deliver superior mold products to our clients. Adhering to the principles of quality first, integrity, and mutual benefit, we strive to exceed our customers' expectations with every project. We welcome collaboration from all sectors and look forward to creating a brighter future together.