High-Precision PVC/WPC Partition Board Mold - Durable, Efficient, and Versatile

- Information

- Product Description

- Video

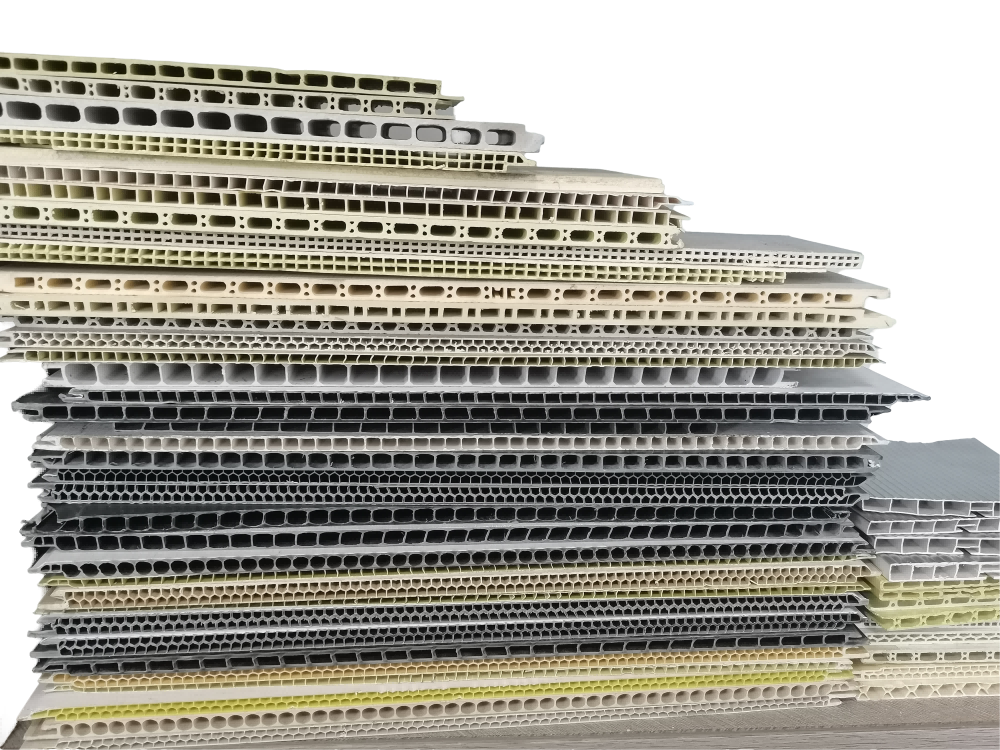

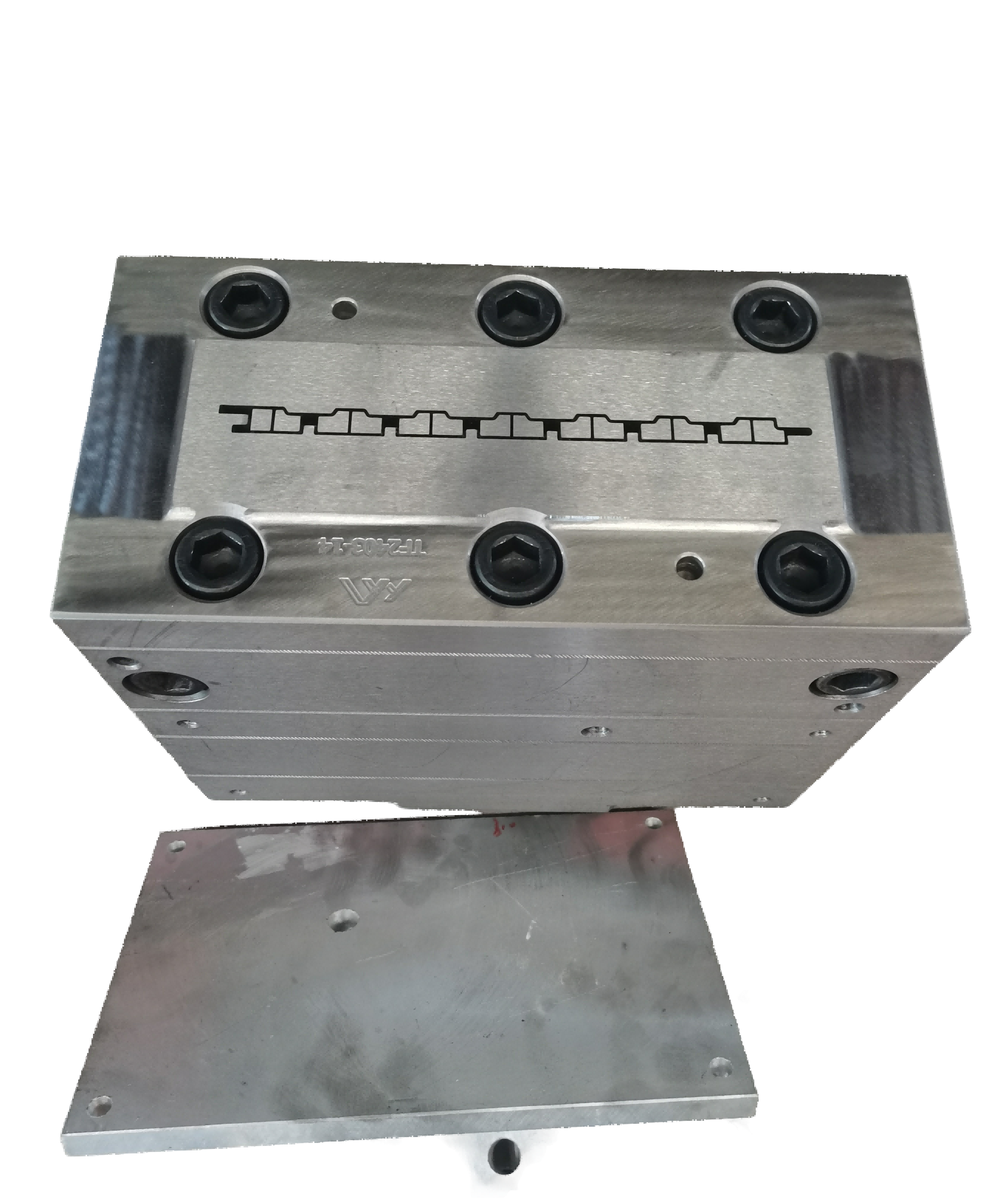

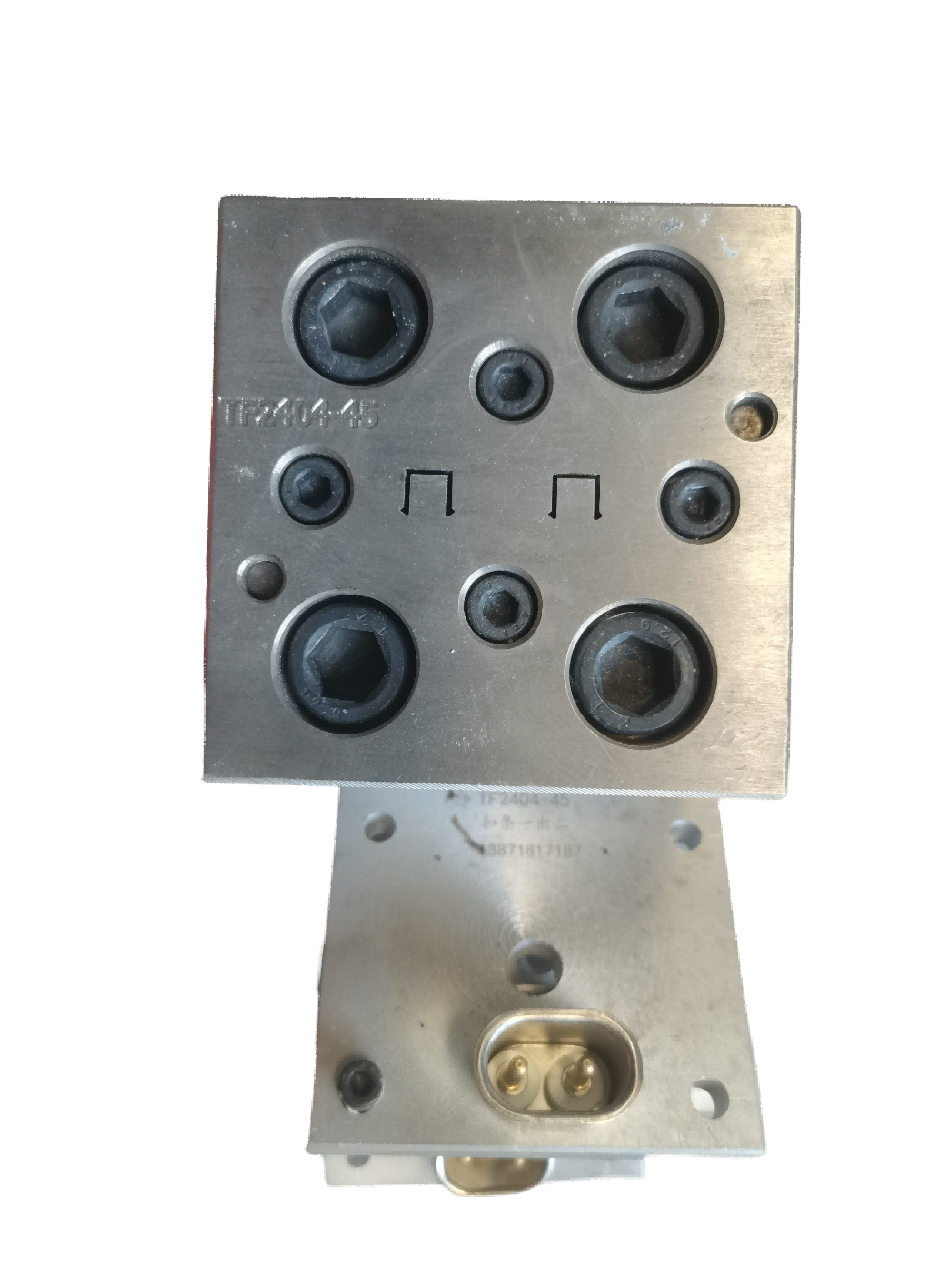

Material and Construction: The PVC/WPC Partition Board Mold is constructed from high-grade steel, known for its durability and resistance to wear and tear. The mold is designed to handle the unique properties of both PVC (Polyvinyl Chloride) and WPC (Wood Plastic Composite) materials, ensuring a smooth molding process and a flawless final product. With meticulous attention to detail, each mold is precision-engineered to produce partition boards with consistent dimensions, clean edges, and a smooth surface finish.

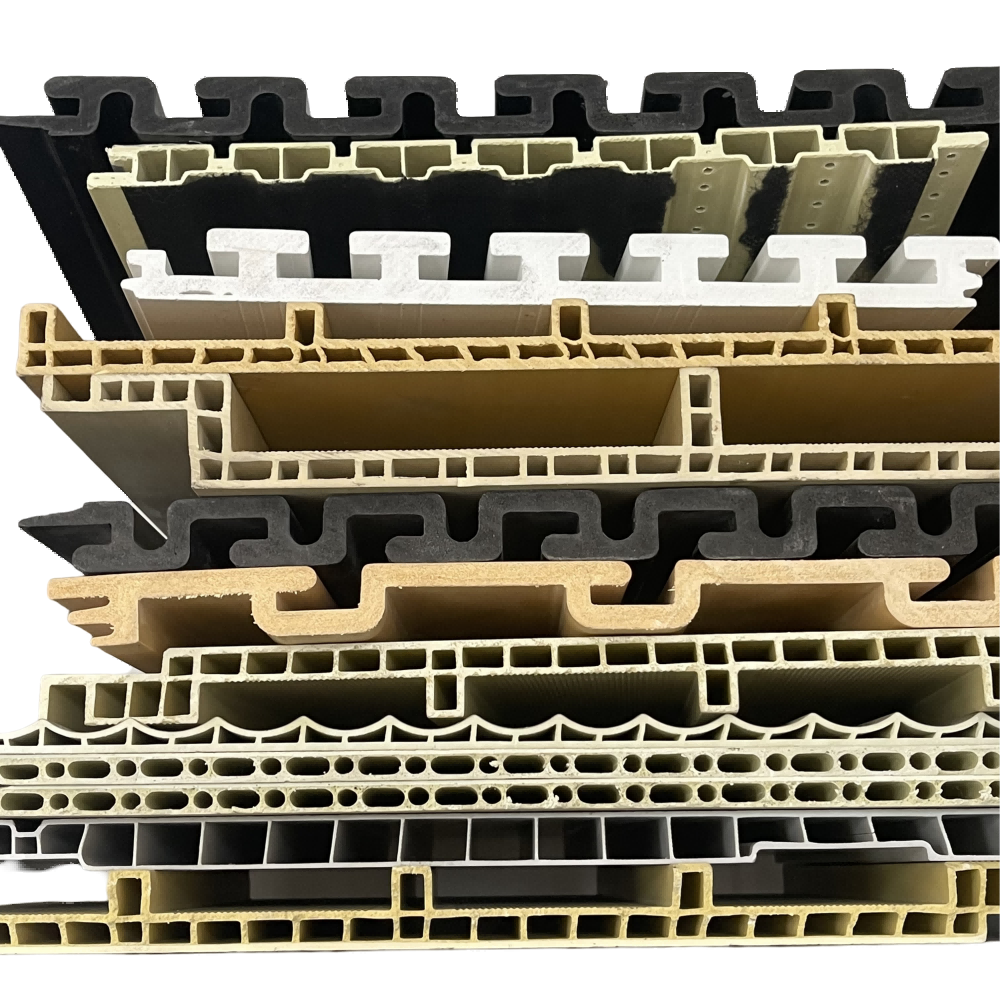

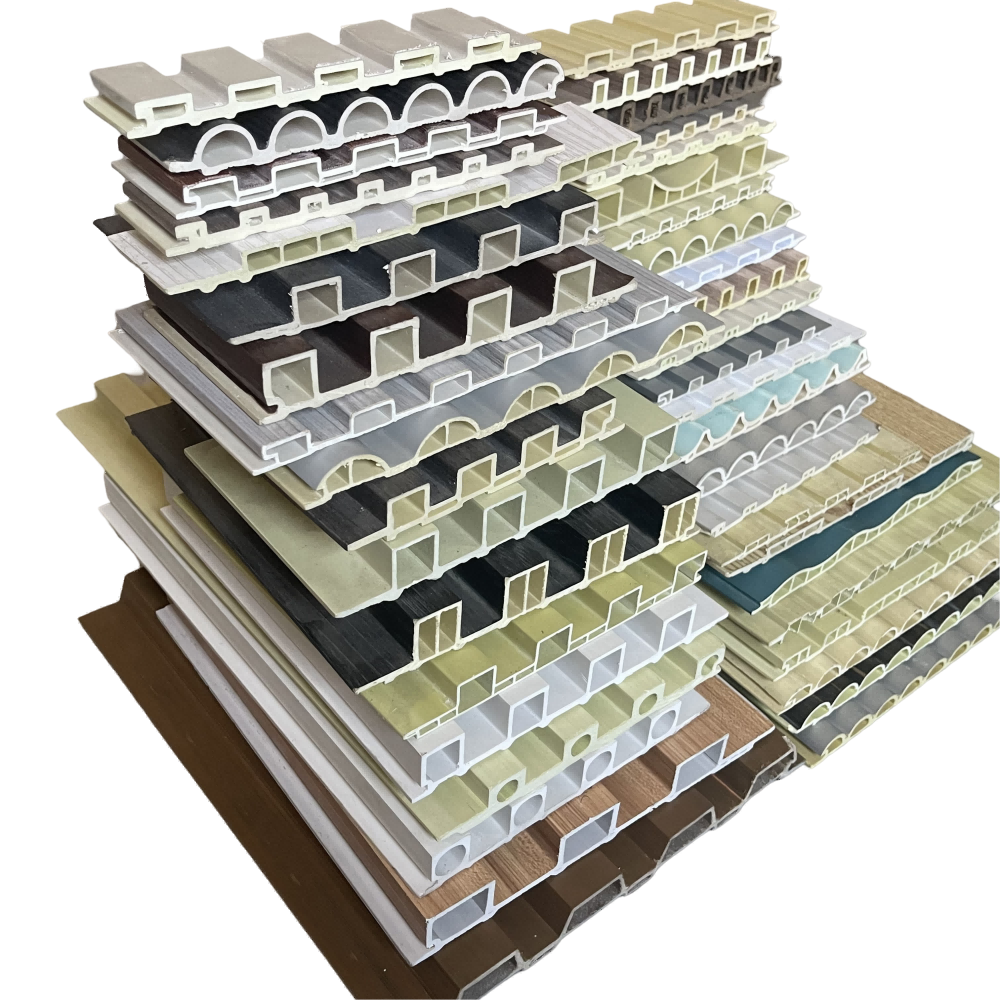

Versatility and Application: This mold is highly versatile and suitable for a wide range of applications. It can be used to produce partition boards for various environments, including offices, schools, hospitals, and homes. The boards produced are ideal for creating temporary or permanent walls, room dividers, and decorative panels. The mold supports the creation of both standard and customized designs, allowing manufacturers to cater to specific client needs and preferences.

Efficiency in Production: The design of the PVC/WPC Partition Board Mold emphasizes efficiency and ease of use. The mold's streamlined structure allows for quick setup, minimal maintenance, and high-speed production, significantly reducing downtime and increasing output. The advanced cooling system integrated into the mold ensures rapid solidification of the material, leading to faster cycle times and higher productivity.

Surface Quality and Finish: The mold is engineered to produce partition boards with an exceptional surface finish. The smooth and flawless surface reduces the need for post-production finishing, saving time and labor costs. Whether the final product is intended to be painted, laminated, or left in its natural state, the high-quality finish provided by our mold ensures that the boards are ready for immediate use.

Customizability: At Xishui Tongfeng Technology Co., Ltd, we understand that every project has unique requirements. Our PVC/WPC Partition Board Mold can be customized to produce boards of various sizes, thicknesses, and designs. Whether you need standard partition boards or bespoke panels with intricate patterns, our mold can be tailored to meet your specifications, ensuring that your end product aligns perfectly with your design vision.

Durability and Longevity: Designed for long-term use, the PVC/WPC Partition Board Mold is built to withstand the rigors of continuous production. The mold's robust construction and high-quality materials ensure that it maintains its precision and performance over time, providing reliable results with every use. This durability translates to lower long-term costs, as the mold requires less frequent replacement or repair.

Environmentally Friendly Production: The mold supports the use of eco-friendly materials such as WPC, which combines wood fibers with recycled plastic, reducing environmental impact. By choosing our mold, manufacturers contribute to sustainable production practices, aligning with global trends toward greener manufacturing.

After-Sales Support and Service: Xishui Tongfeng Technology Co., Ltd offers comprehensive after-sales support to ensure that our customers get the most out of their PVC/WPC Partition Board Mold. Our team of experts is available to provide technical assistance, maintenance tips, and troubleshooting support, ensuring that your production line runs smoothly and efficiently.

Xishui Tongfeng Technology Co., Ltd is proud to present the PVC/WPC Partition Board Mold, a cutting-edge solution designed for the efficient production of high-quality partition boards. This mold combines advanced manufacturing techniques with robust materials to deliver precision-engineered products that meet the diverse needs of the modern construction and interior design industries. Whether you are creating partitions for offices, residential spaces, or commercial establishments, our PVC/WPC Partition Board Mold ensures that your production process is smooth, efficient, and produces superior results.

Product Details

Material and Construction: The PVC/WPC Partition Board Mold is constructed from high-grade steel, known for its durability and resistance to wear and tear. The mold is designed to handle the unique properties of both PVC (Polyvinyl Chloride) and WPC (Wood Plastic Composite) materials, ensuring a smooth molding process and a flawless final product. With meticulous attention to detail, each mold is precision-engineered to produce partition boards with consistent dimensions, clean edges, and a smooth surface finish.

Versatility and Application: This mold is highly versatile and suitable for a wide range of applications. It can be used to produce partition boards for various environments, including offices, schools, hospitals, and homes. The boards produced are ideal for creating temporary or permanent walls, room dividers, and decorative panels. The mold supports the creation of both standard and customized designs, allowing manufacturers to cater to specific client needs and preferences.

Efficiency in Production: The design of the PVC/WPC Partition Board Mold emphasizes efficiency and ease of use. The mold's streamlined structure allows for quick setup, minimal maintenance, and high-speed production, significantly reducing downtime and increasing output. The advanced cooling system integrated into the mold ensures rapid solidification of the material, leading to faster cycle times and higher productivity.

Surface Quality and Finish: The mold is engineered to produce partition boards with an exceptional surface finish. The smooth and flawless surface reduces the need for post-production finishing, saving time and labor costs. Whether the final product is intended to be painted, laminated, or left in its natural state, the high-quality finish provided by our mold ensures that the boards are ready for immediate use.

Customizability: At Xishui Tongfeng Technology Co., Ltd, we understand that every project has unique requirements. Our PVC/WPC Partition Board Mold can be customized to produce boards of various sizes, thicknesses, and designs. Whether you need standard partition boards or bespoke panels with intricate patterns, our mold can be tailored to meet your specifications, ensuring that your end product aligns perfectly with your design vision.

Durability and Longevity: Designed for long-term use, the PVC/WPC Partition Board Mold is built to withstand the rigors of continuous production. The mold's robust construction and high-quality materials ensure that it maintains its precision and performance over time, providing reliable results with every use. This durability translates to lower long-term costs, as the mold requires less frequent replacement or repair.

Environmentally Friendly Production: The mold supports the use of eco-friendly materials such as WPC, which combines wood fibers with recycled plastic, reducing environmental impact. By choosing our mold, manufacturers contribute to sustainable production practices, aligning with global trends toward greener manufacturing.

After-Sales Support and Service: Xishui Tongfeng Technology Co., Ltd offers comprehensive after-sales support to ensure that our customers get the most out of their PVC/WPC Partition Board Mold. Our team of experts is available to provide technical assistance, maintenance tips, and troubleshooting support, ensuring that your production line runs smoothly and efficiently.

Company Background

Xishui Tongfeng Technology Co., Ltd is a distinguished name in the plastic molding industry, located in the historic and strategically positioned city of Huangshi. We specialize in the design and manufacturing of high-quality plastic molds, supported by advanced processing equipment and a team of skilled professionals. Our commitment to innovation, quality, and customer satisfaction drives us to continually push the boundaries of what is possible in mold design and manufacturing.

We welcome partners and customers from all industries to visit our facilities, explore our offerings, and collaborate with us in creating a successful future together.