High-Precision WPC Decorative Board Mold - Engineered for Elegant and Durable Panels

- Information

- Product Description

- Video

Material and Manufacturing Process:

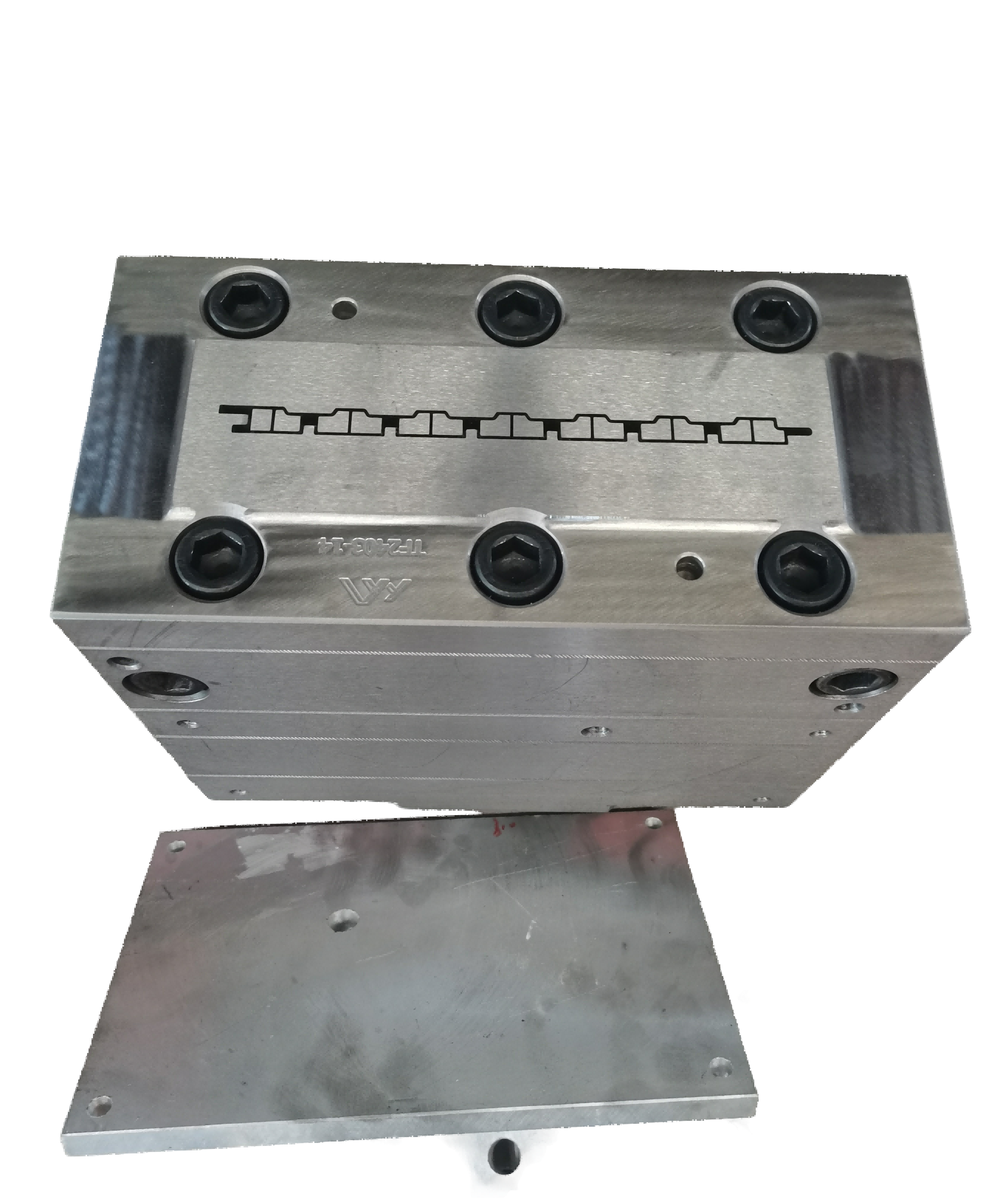

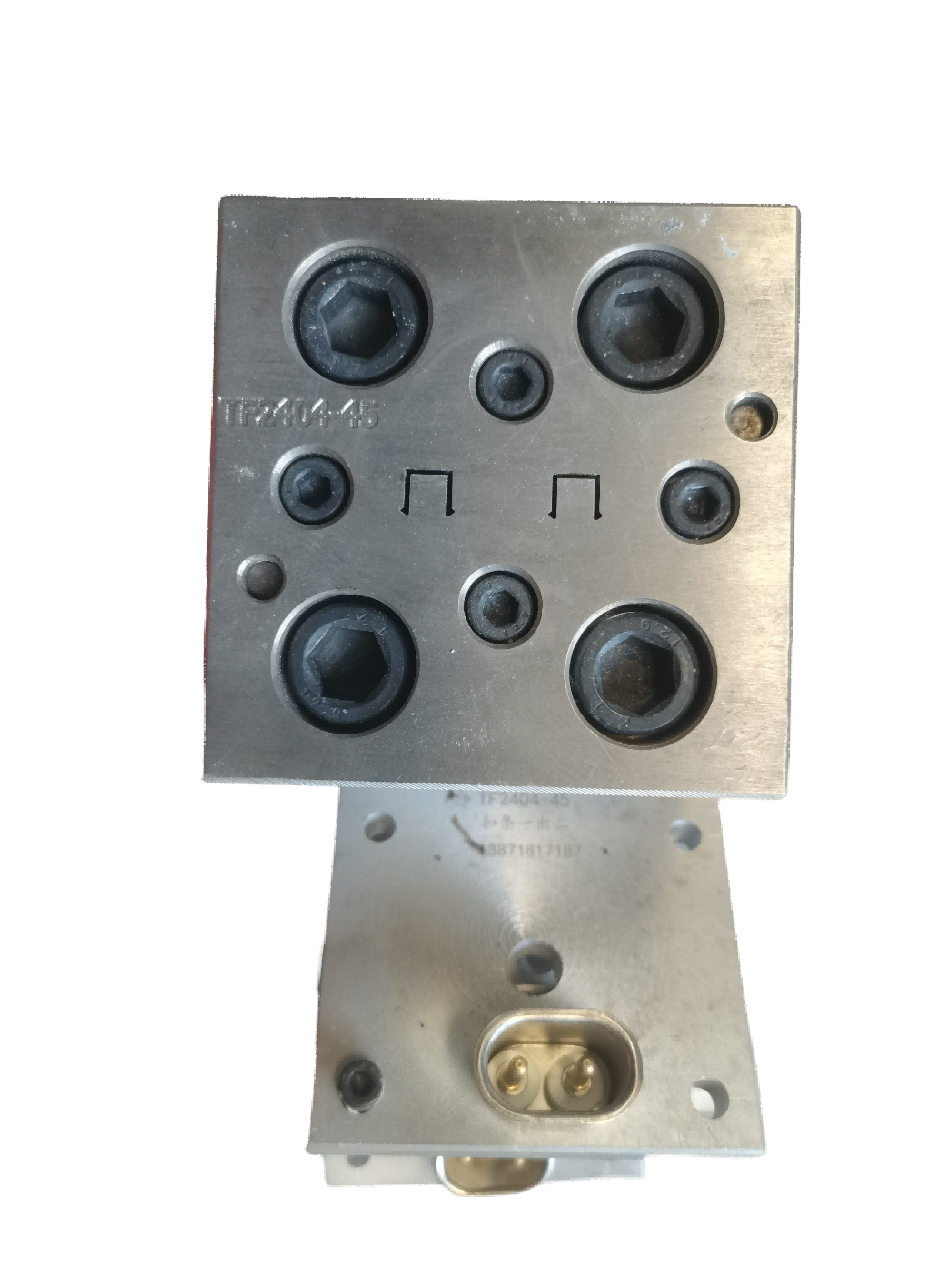

The WPC Decorative Board Mold is constructed from high-strength, corrosion-resistant steel, which ensures long-lasting durability and consistent performance. The mold undergoes a comprehensive manufacturing process that includes advanced CNC machining, heat treatment, and surface polishing. This ensures that the mold maintains its precision and quality, even after extensive use in high-volume production settings. The mold's robust construction minimizes maintenance needs, offering a long service life and reducing operational downtime.Aesthetic Versatility and Design:

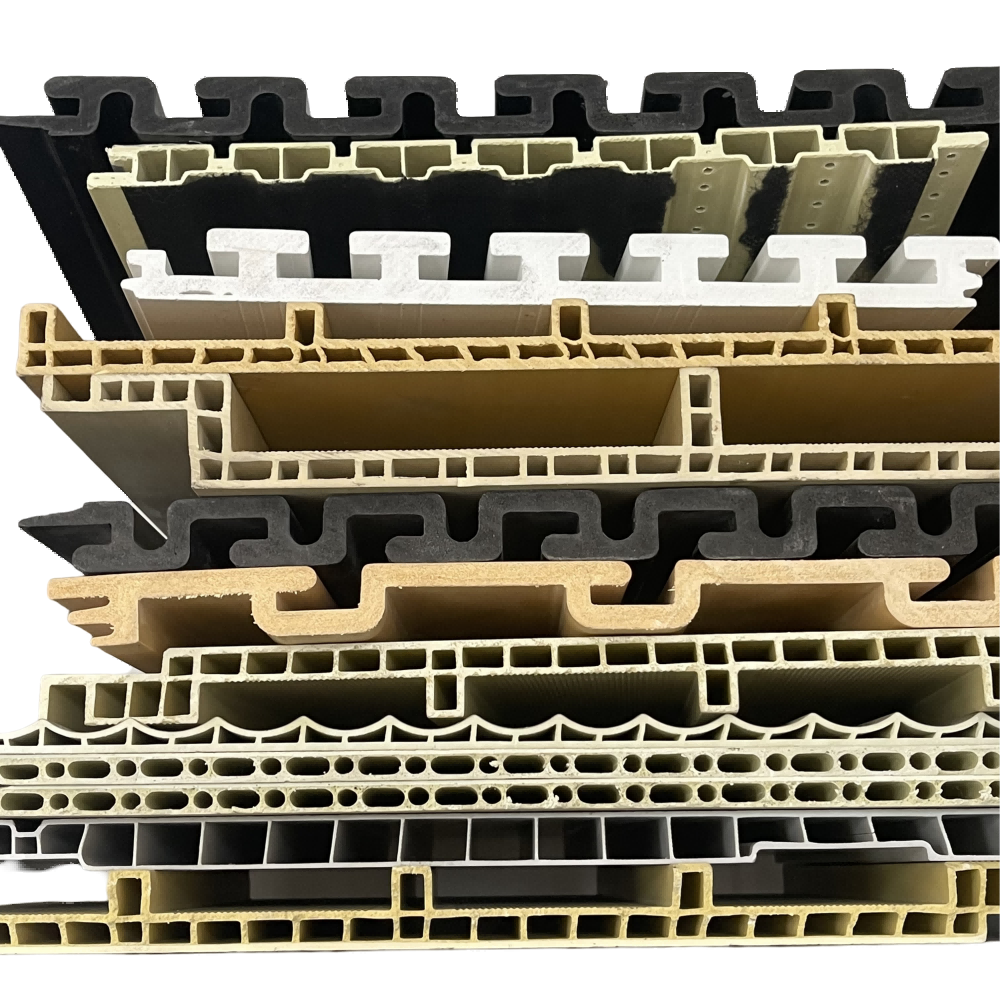

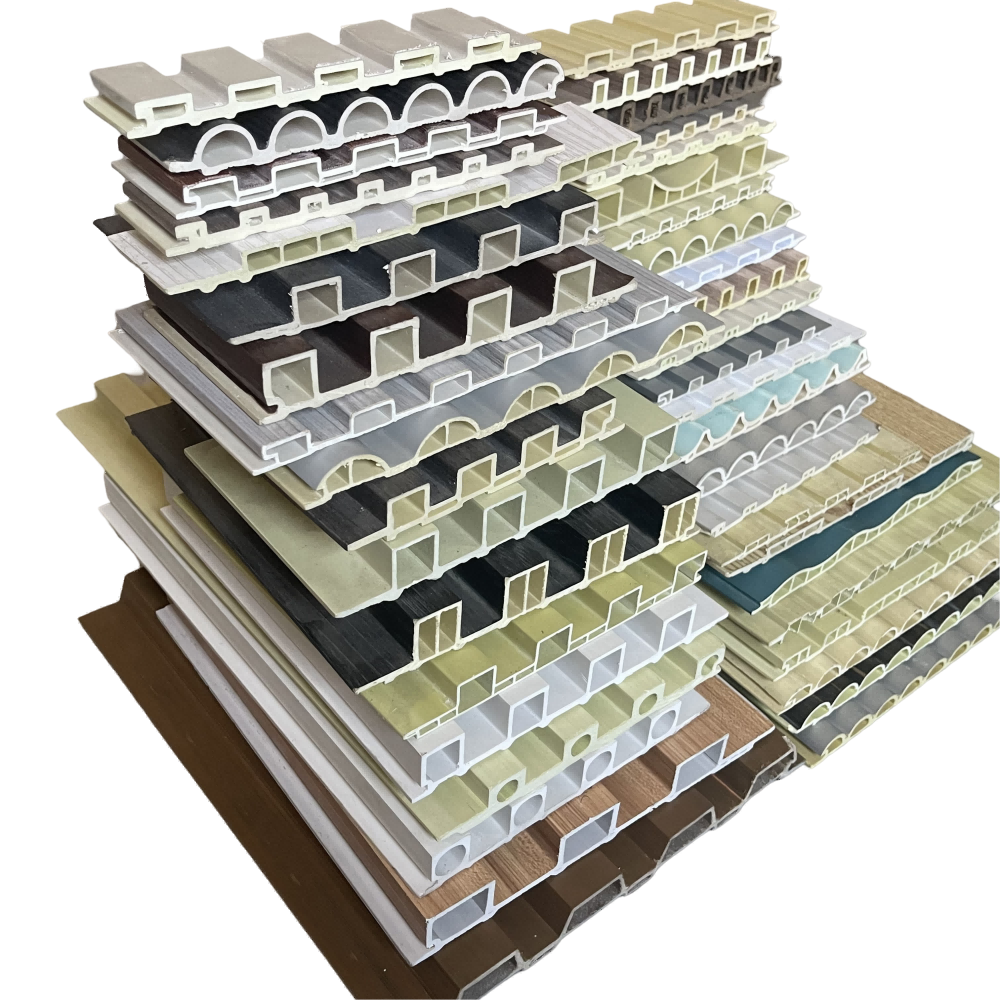

Our WPC Decorative Board Mold is engineered to produce decorative boards in a variety of textures, patterns, and finishes. Whether you're aiming for a natural wood grain look, a sleek modern finish, or a custom design, this mold provides the flexibility to meet diverse design requirements. The mold's precision engineering allows for intricate detailing, ensuring that the decorative boards produced are visually appealing and enhance the overall aesthetic of any project, whether it's a residential, commercial, or public space.Environmental Sustainability:

The WPC Decorative Board Mold is designed to work with eco-friendly WPC materials, which are made from a combination of recycled wood fibers and plastic. This makes the decorative boards not only durable and resistant to weathering but also environmentally responsible. By using this mold, manufacturers can produce sustainable products that contribute to reducing environmental impact while meeting the growing demand for green building materials.Durability and Performance:

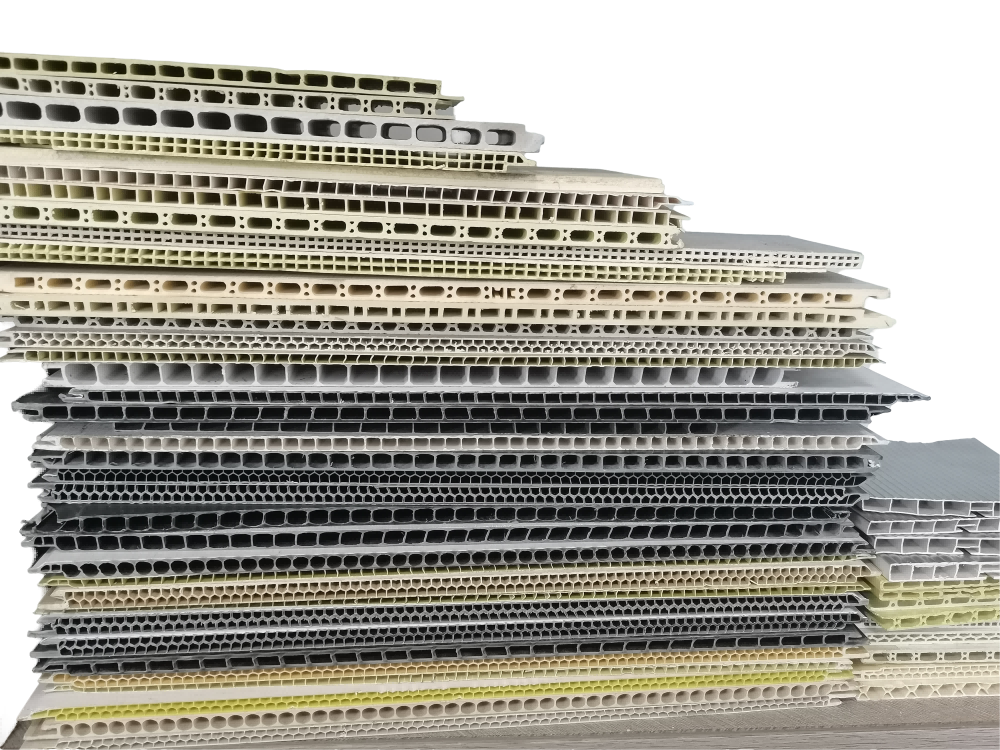

The decorative boards produced with our mold are designed to withstand harsh environmental conditions, including moisture, UV exposure, and temperature fluctuations. This makes them ideal for both indoor and outdoor applications, such as wall cladding, ceiling panels, and exterior facades. The boards are resistant to rot, decay, and insect damage, ensuring a long-lasting and low-maintenance solution for end users. The mold's design ensures that each board produced is of consistent quality, with tight tolerances that ensure easy installation and a perfect fit.Efficiency and Cost Savings:

The WPC Decorative Board Mold is designed for high-efficiency production, minimizing material waste and reducing production cycle times. This results in lower manufacturing costs and higher output rates, providing manufacturers with a competitive edge in the market. The mold’s durability and precision also reduce the need for post-production finishing, such as sanding or trimming, further enhancing production efficiency and cost-effectiveness.After-Sales Support and Services:

At Xishui Tongfeng Technology Co., Ltd, we are committed to providing comprehensive after-sales support. Our team of experienced professionals is available to assist with mold installation, setup, and any technical issues that may arise. We offer ongoing technical support and maintenance services to ensure that your mold continues to operate at peak performance. Our goal is to build long-term relationships with our customers, ensuring their success and satisfaction through reliable products and dedicated service.

Xishui Tongfeng Technology Co., Ltd introduces the WPC Decorative Board Mold, meticulously designed to produce high-quality, aesthetically pleasing wood-plastic composite (WPC) decorative boards. These molds are crafted with precision to ensure that each decorative board meets the highest standards of durability, design, and environmental sustainability. Ideal for both interior and exterior applications, our molds are perfect for manufacturers aiming to produce decorative boards that enhance the beauty and functionality of any space.

Product Details

Material and Manufacturing Process:

The WPC Decorative Board Mold is constructed from high-strength, corrosion-resistant steel, which ensures long-lasting durability and consistent performance. The mold undergoes a comprehensive manufacturing process that includes advanced CNC machining, heat treatment, and surface polishing. This ensures that the mold maintains its precision and quality, even after extensive use in high-volume production settings. The mold's robust construction minimizes maintenance needs, offering a long service life and reducing operational downtime.Aesthetic Versatility and Design:

Our WPC Decorative Board Mold is engineered to produce decorative boards in a variety of textures, patterns, and finishes. Whether you're aiming for a natural wood grain look, a sleek modern finish, or a custom design, this mold provides the flexibility to meet diverse design requirements. The mold's precision engineering allows for intricate detailing, ensuring that the decorative boards produced are visually appealing and enhance the overall aesthetic of any project, whether it's a residential, commercial, or public space.Environmental Sustainability:

The WPC Decorative Board Mold is designed to work with eco-friendly WPC materials, which are made from a combination of recycled wood fibers and plastic. This makes the decorative boards not only durable and resistant to weathering but also environmentally responsible. By using this mold, manufacturers can produce sustainable products that contribute to reducing environmental impact while meeting the growing demand for green building materials.Durability and Performance:

The decorative boards produced with our mold are designed to withstand harsh environmental conditions, including moisture, UV exposure, and temperature fluctuations. This makes them ideal for both indoor and outdoor applications, such as wall cladding, ceiling panels, and exterior facades. The boards are resistant to rot, decay, and insect damage, ensuring a long-lasting and low-maintenance solution for end users. The mold's design ensures that each board produced is of consistent quality, with tight tolerances that ensure easy installation and a perfect fit.Efficiency and Cost Savings:

The WPC Decorative Board Mold is designed for high-efficiency production, minimizing material waste and reducing production cycle times. This results in lower manufacturing costs and higher output rates, providing manufacturers with a competitive edge in the market. The mold’s durability and precision also reduce the need for post-production finishing, such as sanding or trimming, further enhancing production efficiency and cost-effectiveness.After-Sales Support and Services:

At Xishui Tongfeng Technology Co., Ltd, we are committed to providing comprehensive after-sales support. Our team of experienced professionals is available to assist with mold installation, setup, and any technical issues that may arise. We offer ongoing technical support and maintenance services to ensure that your mold continues to operate at peak performance. Our goal is to build long-term relationships with our customers, ensuring their success and satisfaction through reliable products and dedicated service.

Company Background

Xishui Tongfeng Technology Co., Ltd is a leading manufacturer of plastic molds, located in the historically rich city of Huangshi. With advanced processing equipment and a highly skilled team, our company is dedicated to producing top-quality molds for a variety of applications. Our business philosophy emphasizes "quality first, integrity, mutual benefit, continuous innovation, and striving for excellence," ensuring that we provide our customers with the best products and services in the industry.

We warmly welcome friends from all industries to visit our company, discuss business opportunities, and collaborate with us to create a brighter future!